Blatner Tools

Groundbreaking and cutting-edge

This course teaches the tools and techniques that make the 2020 version of this powerful page-layout application so fun and easy to use. Instructor David Blatner gets you up to speed fast, with a. 2020 Blattner Feedlot Construction, Inc. ALL RIGHTS RESERVED. Powered by Agrinux Solutions, LLCAgrinux Solutions, LLC. Blatner's Auto at Autotrader. View new, used and certified cars and get auto financing from a North Tonawanda car dealer.

Blair Equipment's tools are used by collision and custom shops make automotive body repairs, remove spotwelds & cut holes, faster and more accurate. Script Manager makes it easy to use scripts, even for beginner users. You can even embed scripts.

The world’s only hand tools that can “sandblast”. The patented Bristle Blaster® Technology removes corrosion and coatings quickly and thoroughly. At the same time, the Bristle Blaster® creates surface preparation grades comparable with Sa2½ (SSPC-SP 10/NACE No. 2) to Sa3 (SSPC-SP 5/NACE No. 1) and roughness levels of up to 120 µm Rz.

New innovation

The patented Bristle Blaster® is the first hand-held brush belt system in the world that produces a quality of surface roughness and a result comparable to that achieved by sandblasting. The Bristle Blasting process is a new innovation that both removes corrosion and generates an anchor profile by using a specially designed rotary bristle tool. This tool consists of wire bristle tips that are bent forward and dynamically tuned to a hand-held power tool which operates at approximately 2,500 rpm.

Mechanical principles

Bristle tips are designed to strike the corroded surface with kinetic energy that is equivalent to standard processes that use grit blast media. Immediately after the bristle tips strike the corroded steel surface, they retract (i.e., “rebound”) from the surface, which results in both corrosion removal and a micro-indentation that exposes fresh surface. Consequently, surfaces that have been treated by the Bristle Blasting tool have a texture and visual cleanliness that mimics those obtained by traditional grit blasting processes.

The Bristle Blaster® is a specially designed rotary bristle tool that both removes corrosion and generates an anchor profile.

The Bristle Blaster® is a specially designed rotary that both removes corrosion and generates an anchor profile.

Bristle Blaster®

Cordless

Soon available! The new cordless technology for the Bristle Blaster®, including the deadman switch. It includes the anti-vibrating handle, a new robust fronthead including the new patented quick click & go adaptor system.

What results does the Bristle Blaster® Technology deliver?

The patented Bristle Blaster® Technology is capable of removing corrosion and coatings quickly and thoroughly. At the same time, the Bristle Blaster® creates surface preparation grades comparable with Sa 2½–3 and roughness levels of up to 120 µm Rz.

Example: Roughness levels of 65–83 µm were achieved on a pipe made of API-5L-X42 steel with rust grade D.

What is the working speed of the Bristle Blaster®?

The working speed of the Bristle Blaster® depends on the following factors:

- Hardness and quality of the base material

- Rust grades present (A, B, C, D)

- Coatings applied (type, thickness)

- Scale layer

- Adhesive residues

Example: A working speed of 1.1 m² per hour was achieved on a pipe made of API-5L-X42 steel with rust grade D.

How long is the service life of a Bristle Blaster® Belt, an Accelerator Bar and an Adaptor System?

The average service life of a Bristle Blaster® Belt is approximately one hour which is about 1 – 1.5 m2 of the surface. Light flashrusted surfaces can be treated at a rate of 1.1 m2 per hour. On some applications e.g. surface preparation on plain weld seams, not coated, construction steel etc. even lifetime of Bristle Blaster® Belts up to 3 m2 has been experienced.

We roughly estimate that an Accelerator bar and an Adaptor system ought to be changed after having used approx. 50 Bristle Blaster® Belts.

The following factors affect the rate of wear:

- Hardness and quality of the base material

- Actual conditions of the substrate to be treated such as grade of corrosion (A, B, C, D)

- Coatings applied (type, thickness, hardness)

- Scale layer

- Adhesive residues

- Surface Shape

- Correct handling of the tool by the operator

Blatner Tools Website

What applications are Bristle Blaster® Belts made of stainless steel used for?

Bristle Blaster® Belts made of stainless steel are used exclusively to prepare nonferrous metals, such as aluminum and stainless steel. Together with the matching Accelerator Bars made of stainless steel, they prevent the surface being prepared from becoming contaminated and the contact corrosion this would lead to.

Can I also use Bristle Blaster® Belts on other drive units?

No! Bristle Blaster® Belts can only be used on MONTI’s Bristle Blaster® Pneumatic and Electric drive units. These drive units are equipped with an Accelerator Bar that increases the kinetic energy of the bristles many times over. What’s more, they are specially matched in respect of speed and torque for use with Bristle Blaster® Belts. Bristle Blaster® Belts only produce the desired results when used with the Bristle Blaster® drive units.

Why is the compressed-air supply so important to the functionality of Bristle Blaster® technology?

The Air Pressure Regulators supplied with the set regulate the optimum operating pressure and therefore the rotational speed of the Bristle Blaster®. If this speed is too fast, the individual bristle tips cannot strike the base material properly: All they do is scrape across the surface and they fail to generate the necessary surface roughness. The Air Pressure Regulators included in the scope of delivery of the Bristle Blaster® Pneumatic guarantee the ideal operating pressure for our technology: 6.2 bar for 23 mm belts and 5.2 bar for 11 mm belts.

What servicing work does the Bristle Blaster® need?

Pneumatic

Blatner Tools

The compressed-air motor of the Bristle Blaster® Pneumatic must be lubricated every time before it is used. All you have to do is put a few drops of low-viscosity oil into the compressed-air connection. Proper lubrication ensures that the tool enjoys a longer service life and is a precondition for warranty claims.

Electric

This tool should only be serviced by specialists trained in the repair of power tools or by other appropriately qualified tool servicing staff. Always make sure that the tool is switched off and disconnected from the power supply before carrying out servicing work.

Clean the motor housing every time after using the tool and, in particular, blow out the fan with compressed air to remove any dust.

If a Bristle Blaster® Belt tears at the seam, it has probably be used together with a worn adapter system. As time passes, this forms a sharp edge at the webs that connect the two shells. These sharp metal edges can cut the seam and destroy the belt. Consequently, an adapter system should be replaced after approximately 50 operating hours.

Where can I find instructions on how to use the Bristle Blaster®?

It is essential that you know how to work correctly with Bristle Blaster® Technology. You can find appropriate instructions in the user manual. We also recommend that you watch our application film.

Why do I need to attend a product training session?

Bristle Blaster® Technology requires that it is used in accordance with specific guidelines and in a certain way. We would like to teach you this by offering you a product training seminar.

We market our patented Bristle Blaster® Technology through a global network of importers. We serve the German market ourselves. Our subsidiary, MONTI Tools Inc., in Houston/Texas, is responsible for the North American market.

No matter where you purchase your Bristle Blaster®, you can expect to be welcomed by a competent partner, who will provide you with excellent personal aftersales service in addition to obligatory product training.

Blatner Tools Distributors

What is the difference between the Bristle Blaster® and the MBX®?

Bristle Blaster® and MBX® make use of two different technologies and are not compatible with one another.

The patented Bristle Blaster® is capable of removing corrosion and coatings quickly and thoroughly. At the same time, it creates surface preparation grades comparable with Sa 2½–3 and roughness levels of up to 120 µm Rz on appropriate steel surfaces.

The MBX® has been designed for use in automobile workshops and paint shops. Its wide range of belts caters for different tasks, such as removing underseal, sealants, rust and paint from bodywork.

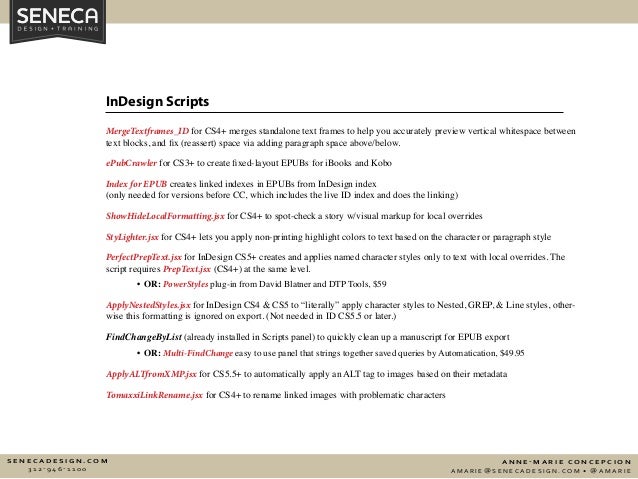

A suite of 12 plug-ins designed by David Blatner to make your work faster, easier and more efficient.

Have you ever wanted to...

- Find which graphic in your InDesign file contains a particular spot color?

- Remove the local text formatting from a whole document?

- Apply a keyboard shortcut to a color swatch, a layer, or any style?

- Automatically convert unstyled text to true paragraph and character styles?

- Compare two similar paragraph styles to see how they're different?

- Place a script in a menu for easy access?

Now You Can!

Yes, you can do all this and a lot more with Blatner Tools, a plug-in suite designed by InDesign guru David Blatner and developed by DTP Tools. See tutorials narrated by David here: YouTube/DTPTools

Increase your Productivity with Blatner Tools

In today's economy, you need to make every second count. We designed the Blatner Tools suite of plug-ins (12 plug-ins offering dozens of new features!) to optimize your InDesign worklow.

It's the difference between working the old way -- slowly and manually formatting text and objects -- or the new Blatner Tools way: automatic style creation; auto fractions; and over 50 new user-customizable shortcuts, including managing layers, swatches, and styles.

While decreasing the time it takes to lay out your files, you can also increase the quality of your output with the help of the Quality Assurance plug-in, which catches common errors such as duplicate objects, incorrect spaces, use of local formatting, short lines, and more. Similarly, the Find Color plug-in uncovers problem colors and lets you fix them! And color and styles reports help ensure styling rules are being followed.

Here are a few more of the many features included in Blatner Tools:

- Script Manager makes it easy to use scripts, even for beginner users. You can even embed scripts in a document for template automation. Blatner Tools also comes with our choice of great third-party scripts, written by some of the best script developers in the industry.

- Remember keeps track of your preference files in case they get lost, and even lets you export and import your preferences and other resource files to share with your workgroup.

- Auto Page helps you avoid overset frames by letting them auto-grow or auto-thread to new pages.

- History LE displays a list of every action, and lets you quickly undo/redo multiple steps, or easily save document states.

You can read more fun facts about this product in interview with David Blatner

In InDesign CC and higher versions Blatner Tools plug-ins ares part of the DTP Tools Cloud bundle. Please install using the Cloud app.

CHANGES IN 1.0.1

- Power Styles

Compare styles now takes 'Next Style' setting into account.

Object styles turned off attributes are now compared too. - Text Controls

The 'Vertically justify using leading' feature was changed to fit text to frame using leading - it now works in overset frames too. - Quality Assurance

Quality assurance now detects usage of more than one em, en and other white space.

Learn more about Blatner Tools for Adobe InDesign

Related resources

Date published:Jul 7, 2019

Version:direct install

Download size:524 KB

Date published:Jul 7, 2019

Version:release

Download size:1400 KB